102, 1st Floor, Building 3, Juze Center, No. 105 Gaoxin Avenue, Shangjie Town, Minhou County, Fujian Province +86-17706919203 [email protected]

Basic Overvie

Advantages And Characteristics

Efficient data transmission and communication:

Real time collection of pressure, flow, liquid level and other signals through sensors,

precise monitoring of various parameters in the sewage treatment process,

and automatic adjustment according to preset programs to ensure stable and compliant treatment effects.

Remote monitoring and management:

With the help of IoT technology, the operation status of the control cabinet Integrated 4G full network access module

and Ethernet module, supports high-speed data transmission, and ensures real-time upload and download of information.

Supports cloud platform access, and can remotely monitor and manage equipment through Web interface, mobile phone APP, etc.

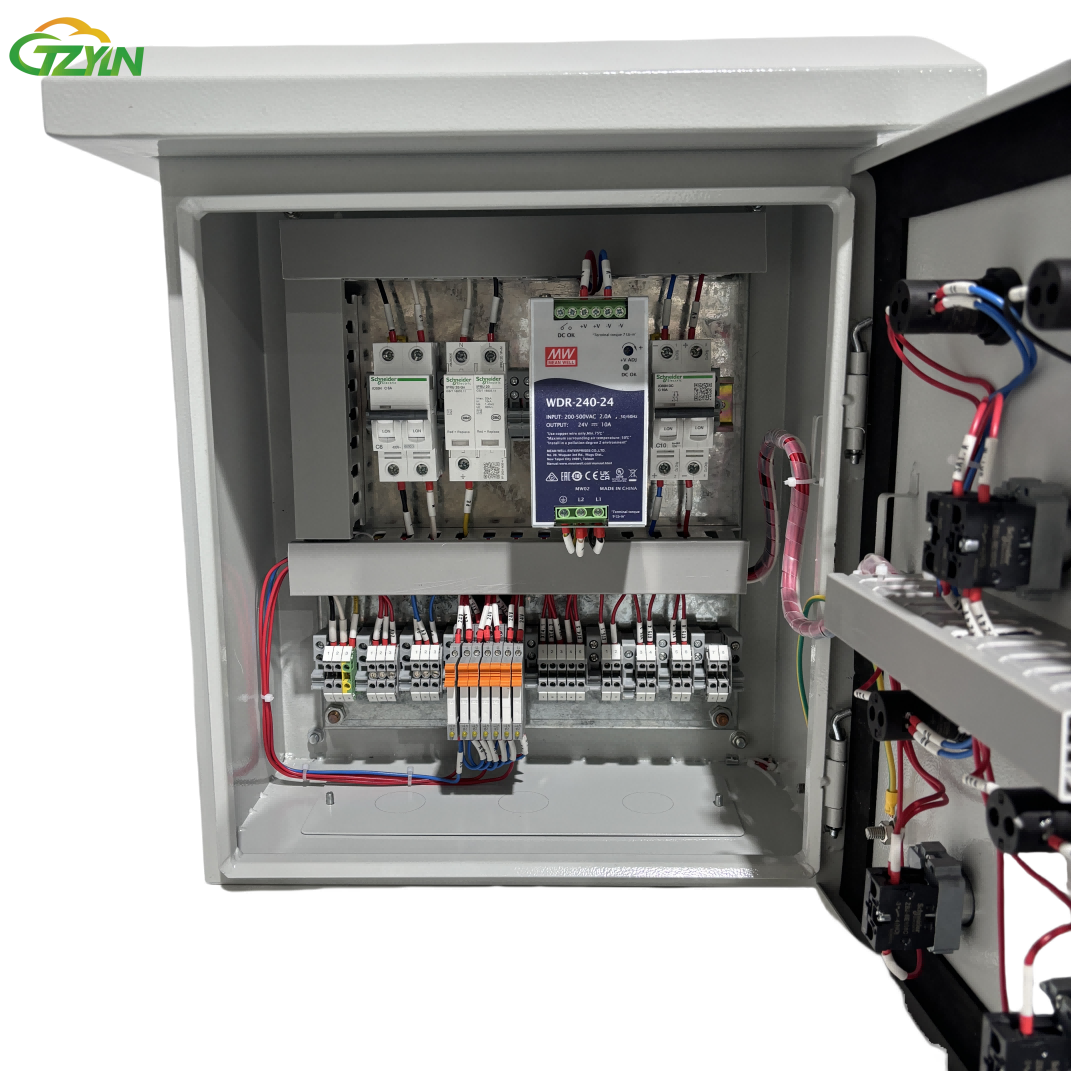

High reliability and environmental adaptability:

The hardware adopts industrial-grade design and has the characteristics of lightning protection,

anti-interference, high temperature resistance and corrosion resistance.

Built-in diagnostic tools and anti-dropping mechanism ensure long-term stable operation of the equipment.

Energy saving and optimization function:

The intelligent energy-saving algorithm can automatically adjust the power output according to

the operating status of the equipment, and the comprehensive power saving rate can reach more than 15%.

Real-time monitoring of equipment energy consumption, optimization of operating parameters,

and reduction of overall energy consumption of the mine.

User-friendliness and convenience:

Supports Web configuration and remote management, and system deployment

and maintenance can be completed without professionals.

The system has self-diagnosis function, which can quickly locate problems and reduce downtime.

|

|

|

|

How to help mine automation?

Mining and excavation

Real-time monitoring of the equipment status of the mining face and excavation face, supporting remote control and automated operation.

Unmanned mining is realized through intelligent systems to reduce personnel risks.

Environmental monitoring and safety warning

Monitor environmental parameters such as gas concentration, dust concentration, and harmful gases, and issue warnings in time.

Support intelligent ventilation system to automatically adjust ventilation according to environmental data.

Equipment monitoring and management

Real-time monitoring and remote control of mining equipment (such as coal mining machines, conveyors, crushers, etc.).

Optimize equipment operating efficiency and reduce energy consumption through data analysis.

Personnel and vehicle management

Real-time positioning of underground personnel and vehicles, and provide early warning information.

Support intelligent inspection system, complete inspection tasks through robots or intelligent devices.

Intelligent transportation and logistics

Realize automated control and remote management of transportation equipment.

Optimize transportation routes and improve transportation efficiency through intelligent scheduling system.

Data visualization and decision support

Present the collected data in the form of dynamic charts, so that managers can grasp the operation status of the mine in real time.

Provide data analysis and decision support to help management optimize production processes.