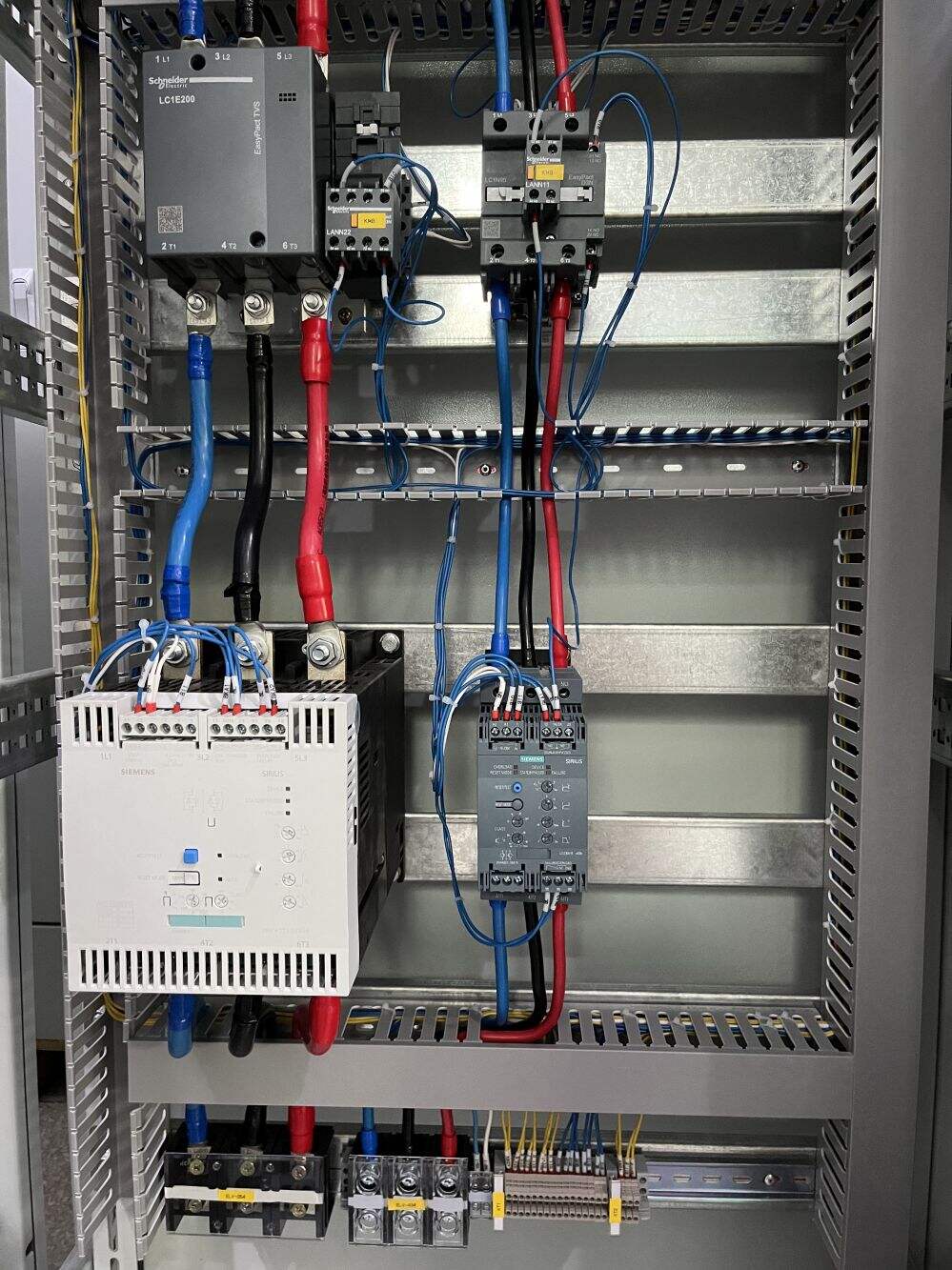

cHNT elektrische paneel

Het CHNT elektrische paneel is een geavanceerd modulair apparaat dat is ontworpen om elektrische energie efficiënt en veilig te beheren en te verdelen. De belangrijkste functies zijn circuitbescherming, energieverdeling en motorbesturing. Technologische kenmerken van het CHNT elektrische paneel omvatten geavanceerde stroomonderbrekers, overspanningsbeveiligingsapparaten en een intelligent monitoringsysteem dat real-time gegevens biedt over energieverbruik en systeemstatus. Dit paneel is veelzijdig en geschikt voor een breed scala aan toepassingen, van wooncomplexen tot industriële faciliteiten, en zorgt voor betrouwbare prestaties in diverse omgevingen.