102, 1st Floor, Building 3, Juze Center, No. 105 Gaoxin Avenue, Shangjie Town, Minhou County, Fujian Province +86-17706919203 [email protected]

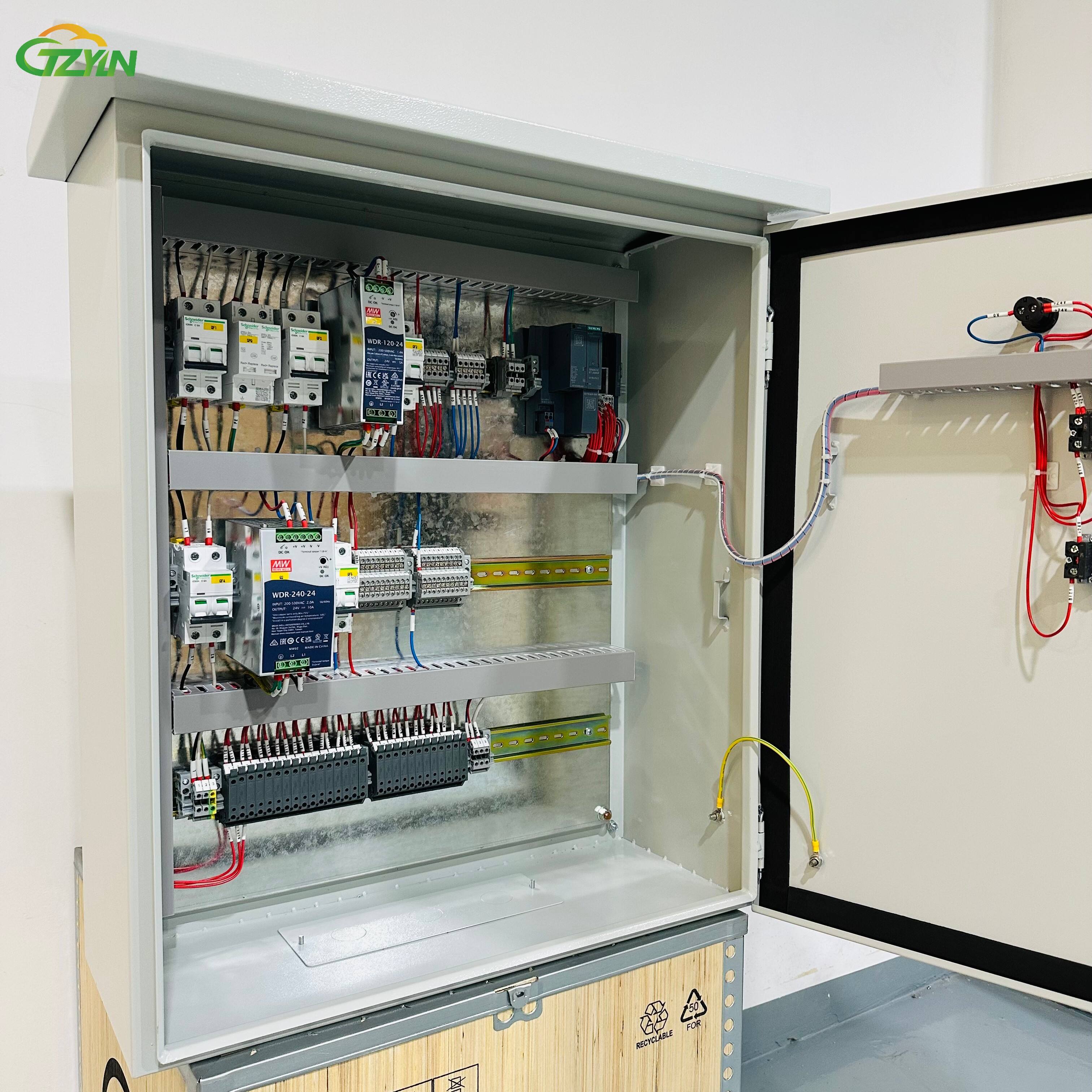

What is control box?

A control box is a device used to manage and control the operation of electrical equipment, and is widely used in industries,

construction, transportation, and other fields. It receives input signals (such as sensor data or manual instructions),

processes the signals, and outputs control instructions to operate equipment (such as motors, water pumps, fans, etc.).

The main functions of the control box include equipment start, stop, speed regulation, protection, and status monitoring.

How does the control box control the water pump?

Data acquisition :

The control box collects the operating status and hydraulic parameters of the water pump in real time

through sensors (such as pressure sensors, liquid level sensors, flow sensors, etc.) connected to

the water pump system. These sensors convert the collected data into electrical signals and transmit them to the control box.

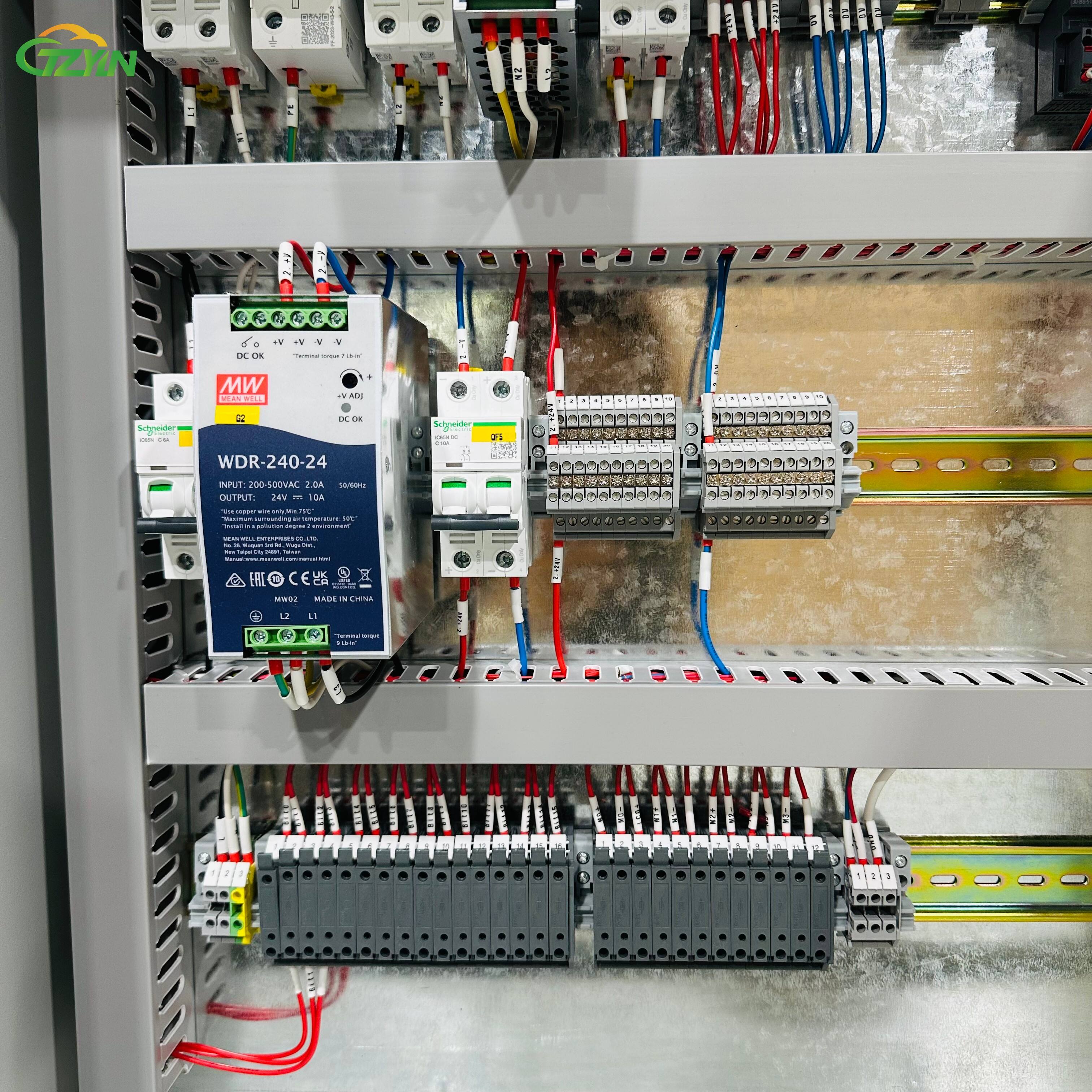

Signal processing:

The controller inside the control box (such as PLC, microprocessor, etc.) analyzes and processes the received signals.

The controller will determine whether the operating status of the water pump is normal and whether control operations

are required based on the preset program and logic. For example:If the pressure sensor detects that the water pressure is lower than the set value,

the controller will determine that the water pump needs to be started.If the liquid level sensor detects that the water level

in the water tank is too high or too low, the controller will issue a corresponding instruction.

Control output:

According to the results of signal processing, the controller sends control instructions to the actuator (such as contactors, relays, etc.)

to start, stop, and adjust the speed of the water pump. For example:

When the water pressure is insufficient, the controller issues an instruction to start the water pump.

When the water level in the water tank reaches the upper limit, the controller issues an instruction to stop the water pump.

Status monitoring and feedback :

The control box can also monitor the operating status of the water pump in real time and feedback this information

to the operator or the main system. If the system is abnormal (such as overload, failure), the control box will automatically

take protective measures (such as cutting off the power supply) and send an alarm signal.

|

|

|

|

|