102, 1st Floor, Building 3, Juze Center, No. 105 Gaoxin Avenue, Shangjie Town, Minhou County, Fujian Province +86 17350199573 [email protected]

In industries such as municipal water supply and sewage treatment, a large number of water pumps are distributed in different areas. Traditional on-site control methods not only consume manpower but also have slow response times, making it difficult to respond to emergencies in a timely manner.

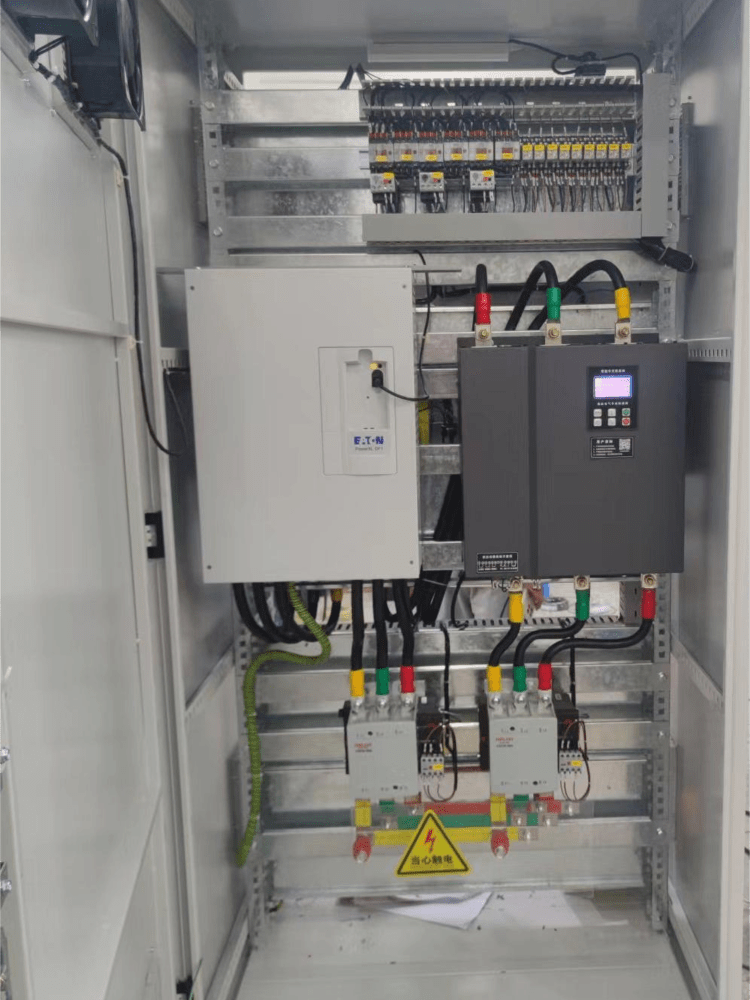

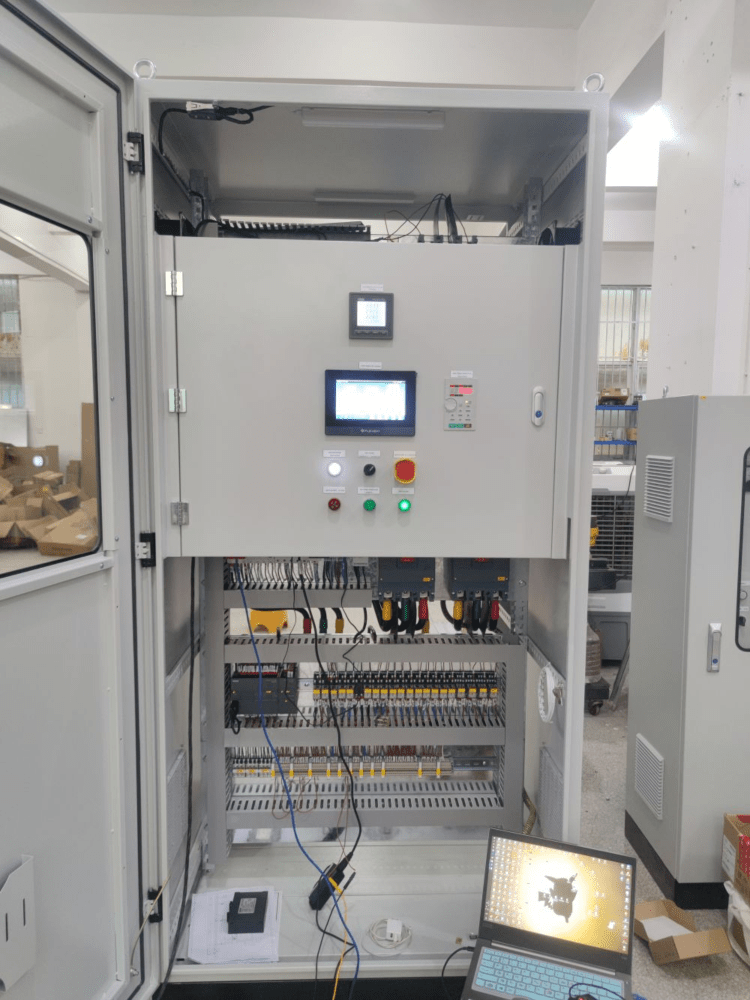

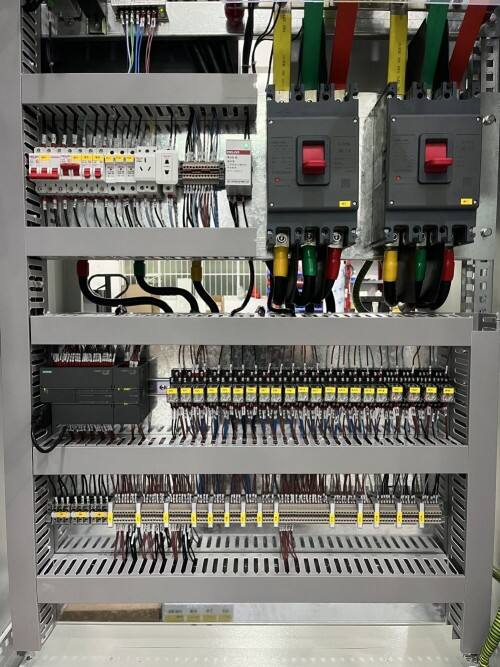

The remote pump control cabinet we have built for the factory integrates advanced IoT technology. Through the Siemens remote monitoring module, operators can monitor the real-time operating status of each water pump in the control center, including parameters such as flow rate, pressure, and motor temperature. When an abnormality occurs, the system will immediately sound an alarm and automatically take corresponding measures, such as switching to a backup pump, adjusting the pump speed, etc.

With the help of a mobile app or computer, staff can remotely start, stop, and adjust the speed of the water pump anytime and anywhere, without the need to go to the site. This solution greatly improves operation and maintenance efficiency, saves labor costs, reduces the number of operation and maintenance personnel in the factory by 20%, and shortens the fault response time to less than 10 seconds.

Our professional sales team are waiting for your consultation.